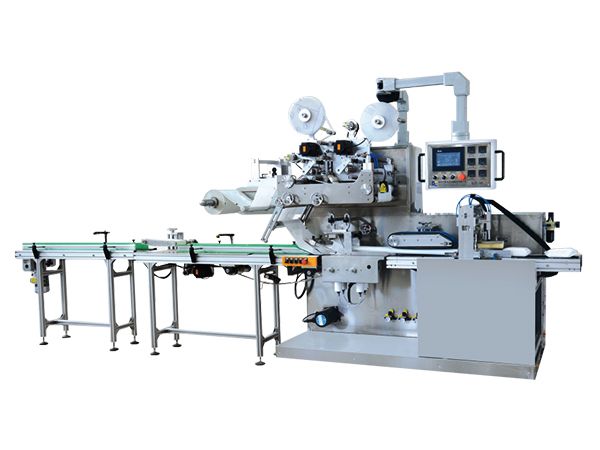

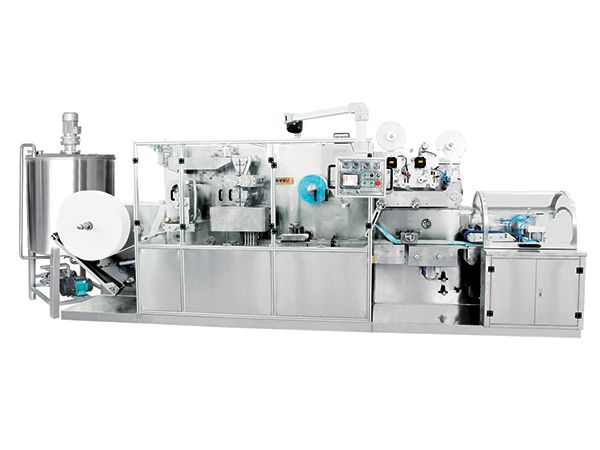

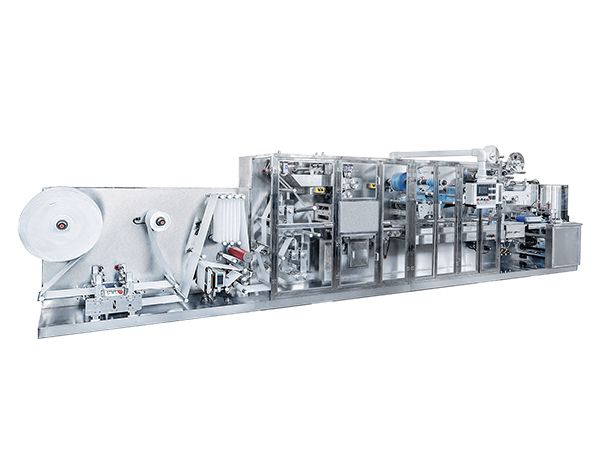

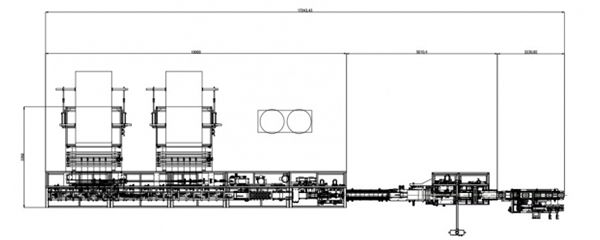

This fully automatic wet wipe folding machine is designed to produce 30-120 pieces per pack of various types of wet wipes, including baby wipes, cosmetic wipes, feminine hygiene wipes, cleaning wipes, antibacterial wipes, kitchen wipes, pet wipes, and disinfectant wipes, making it versatile for personal care, household cleaning, and hygiene applications.

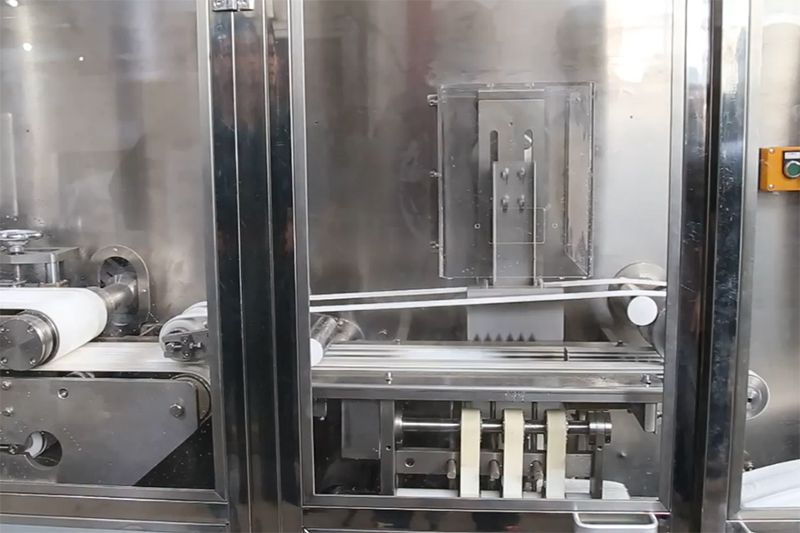

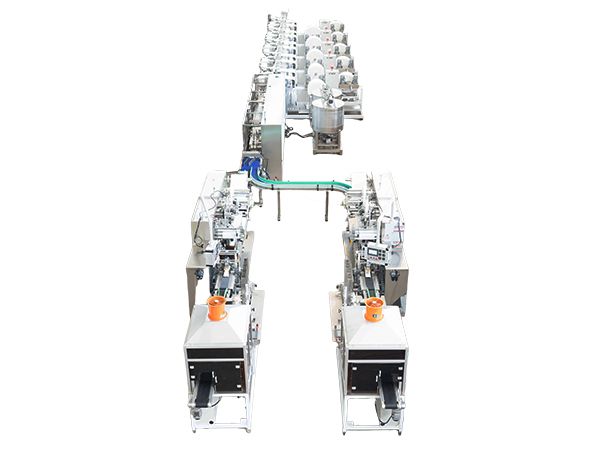

This fully automatic wet wipe production line integrates cutting, folding, wetting, stacking, packaging, and sealing into a single streamlined system. The lid applicator machine can be configured separately and requires only 1-2 operators for supervision.