What types of wet wipe machines are available?

What types of wet wipe machines are available?

Wet wipe machines can be categorized in following ways:

- By automation level: Fully automatic and semi-automatic wet wipe machines.

- By packaging format: Single piece wet wipe machines, flatpack wet wipe machines, and canister wet wipe machines.

- By function: General wet wipe machines, disinfectant wet wipe machines, and baby wet wipe machines.

Most of our wet wipe machines are fully automatic, offering higher production efficiency and consistent quality. Our wet tissue machines support various packaging formats, including single piece, flatpack, and canister packaging, and are widely used in various applications such as baby care, cosmetics, and cleaning.

How does the automation level of wet wipe machines impact its production?

How does the automation level of wet wipe machines impact its production?

Higher automation significantly boosts wet tissue production efficiency by reducing manual operations, labor costs, and human errors. For instance, fully servo-controlled wet wipes machines ensure precise folding, cutting, and wetting, maintaining accuracy and consistency throughout the process. Advanced automation also enables continuous production, minimizing downtime and maximizing output. Some machines feature intelligent monitoring and fault diagnosis systems, reducing maintenance time and prolonging equipment lifespan.

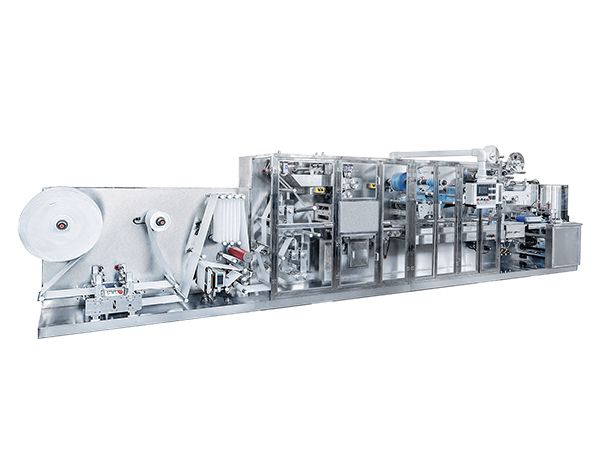

What are the main components of a fully automatic single piece wet wipe machine?

What are the main components of a fully automatic single piece wet wipe machine?

A fully automatic single piece wet wipe machine consists of:

- Unwinding unit

- Web guiding system

- Folding unit

- Slitting unit

- Wetting system

- Packaging system

- Control system

- Machine frame and outer casing

What is the workflow of a fully automatic single piece wet wipe machine?

What is the workflow of a fully automatic single piece wet wipe machine?

Automatic unwinding →Automatic splicing → Synchronous feeding → Longitudinal folding → Wetting → Cut-off and cross-folding → Automatic packaging → Date coding → Longitudinal heat sealing → Transverse heat sealing and cut-off → Empty packs rejection → Defective products rejection → Finished product

What are the advantages of fully automatic wet wipe folding machines?

What are the advantages of fully automatic wet wipe folding machines?

Our fully automatic wet wipe folding machines feature:

- Folding speeds of 4,800-6,000 pieces per minute

- Advanced automation with electric components from Mitsubishi, pneumatic components from AirTAC (Taiwan), and NTN/NSK bearings

- Long-lasting durability with scissor type cutter

- Energy-efficient, stable, and precise operations, suitable for applications in medical, hygiene, and baby care fields

What materials are compatible with fully automatic wet wipe machines?

What materials are compatible with fully automatic wet wipe machines?

These machines support woven and nonwoven materials, including:

- Spun lace nonwoven fabric

- Thermal bond nonwoven fabric

- Wet-strength paper

- Dust-free paper

What are the advantages of your fully automatic wet wipe machines?

What are the advantages of your fully automatic wet wipe machines?

Our automatic wet wipe machine is equipped with Mitsubishi electrical components from Japan, Airtac pneumatic components from Taiwan, and NTN/NSK key bearings from Japan, ensuring high reliability and performance. It features two electrical control modes and adopts an enclosed gearbox combined with a timing belt and universal coupling. Each motor can be operated independently, providing greater flexibility and precision. It also incorporates an innovative rewinding technology, which enhances safety and efficiency during wet wipes production. This effectively addresses the issue of paper rolls separating from their cores during extended storage, ensuring the integrity of the finished products over time.

What types of wet wipes can be produced with your machinery?

What types of wet wipes can be produced with your machinery?

Our wet wipes machines can produce:

Baby wipes, skincare wipes, cosmetic wipes, hygiene wipes, alcohol wipes, leather wipes, hotel wipes, feminine hygiene wipes, cleaning wipes, shoe wipes, and moist toilet paper.

Baby wipes, skincare wipes, cosmetic wipes, hygiene wipes, alcohol wipes, leather wipes, hotel wipes, feminine hygiene wipes, cleaning wipes, shoe wipes, and moist toilet paper.

What are the differences in production processes for various types of wet wipes?

What are the differences in production processes for various types of wet wipes?

- Baby wipes: Require gentle raw materials and sterile production with precise liquid levels to avoid excess moisture.

- Skincare wipes: Include ingredients like glycerin or aloe extract, evenly distributed during production.

- Kitchen wipes: Designed for strong cleaning with special detergents and adequate liquid levels for oil removal.

- Disinfectant and alcohol wipes: Require disinfecting solutions with precise concentration and uniform distribution.

We design tailored processes and choose suitable nonwoven materials and additives for each type of wet wipe.

How can production processes be adjusted to improve wet wipe quality?

How can production processes be adjusted to improve wet wipe quality?

- Optimize raw material selection to ensure quality and performance.

- Strictly filter and purify water and solutions.

- Adjust machine parameters like liquid levels, folding style, and cutting length.

- Implement real-time monitoring and stringent quality control during production.

- Regularly maintain equipment for stable performance and consistent production quality.

Are fully automatic wet wipe machines complex to operate? Do they require professional technicians?

Are fully automatic wet wipe machines complex to operate? Do they require professional technicians?

Our fully automatic wet wipe machines feature intelligent user-friendly interfaces. We offer on-site installation and training or remote guidance based on customer needs. After training, general operators can manage the we wipe machines without requiring specialized technicians.

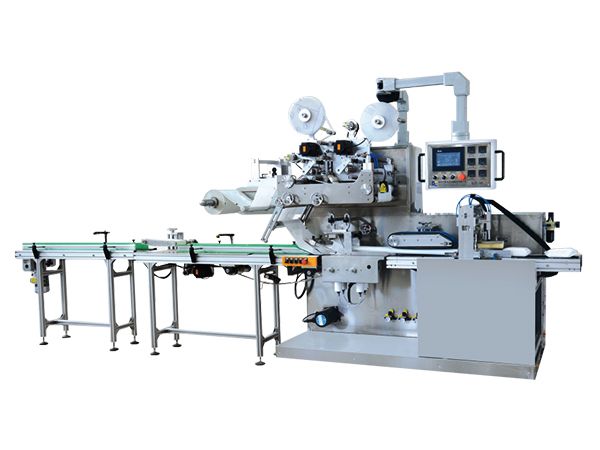

Which machine is suitable for producing small portable wet wipes?

Which machine is suitable for producing small portable wet wipes?

We recommend the DC-2010 Fully Automatic Portable Wet Wipe Machine, ideal for producing 2-10 pcs/pack. It is user-friendly, stable, and highly efficient, with fast size adjustments and stainless-steel components for parts in contact with liquid. Controlled by PLC control system, it meets the requirements of most travel-sized small-package wet wipe production with excellent cost-effectiveness.

E-Mail

E-Mail Phone

Phone Contact Us

Contact Us