Machine

- Production Speed 800-1000 wipes per minute

- Design Speed 1200 wipes per minute

- Fold Types Z-fold (cross folded)

Product

- Open Wipe Length 140-200mm

- Open Wipe Width 140-200mm

- Folded Wipe Length 70-100mm

- Folded Wipe Width 50-80mm

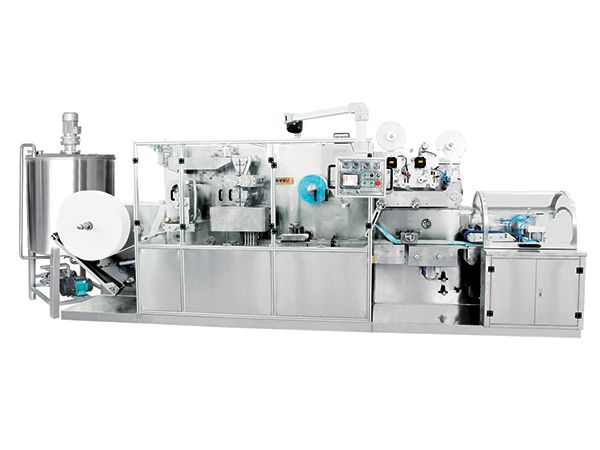

This automatic wet wipes machine is your go-to solution for producing portable, compact, pocket-sized wet wipes. With the ability to easily adjust between 5-30 pieces per pack, it’s the perfect match for on-the-go convenience, giving you the flexibility to meet every customer need, anytime, anywhere. It is ideal for producing a variety of wet wipes, including baby wipes, cosmetic wipes, specialty wipes, and cleaning wipes.

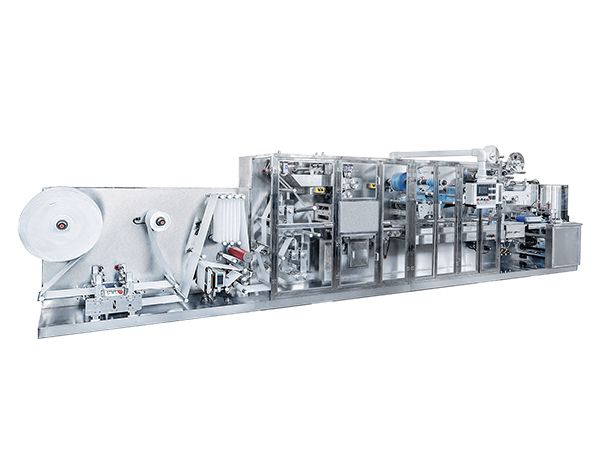

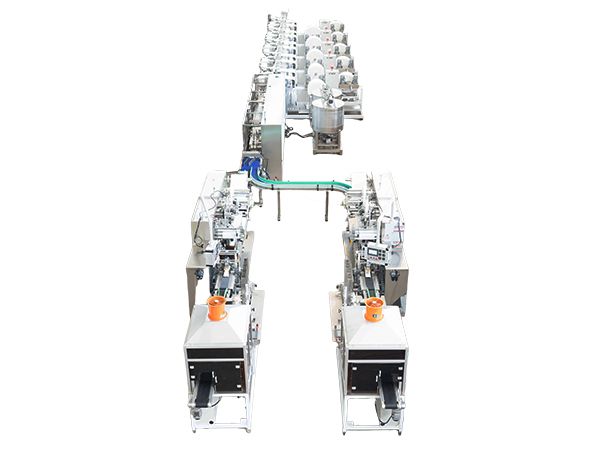

Featuring a dual-lane design for parallel operation, the wet wipes machine has been upgraded with automatic fabric splicing, automatic roll film splicing, and automatic label switching, significantly reducing downtime and enhancing production efficiency. This makes it an ideal choice for small-pack wet wipe production, capable of achieving a stable production speed of 80-100 packs per minute.

With a user-friendly interface, easy parameter settings, and compact design, the machine is simple to operate, maintain, and clean. It incorporates advanced technology and high-quality materials, ensuring high reliability and consistent quality, providing users with an excellent production experience.

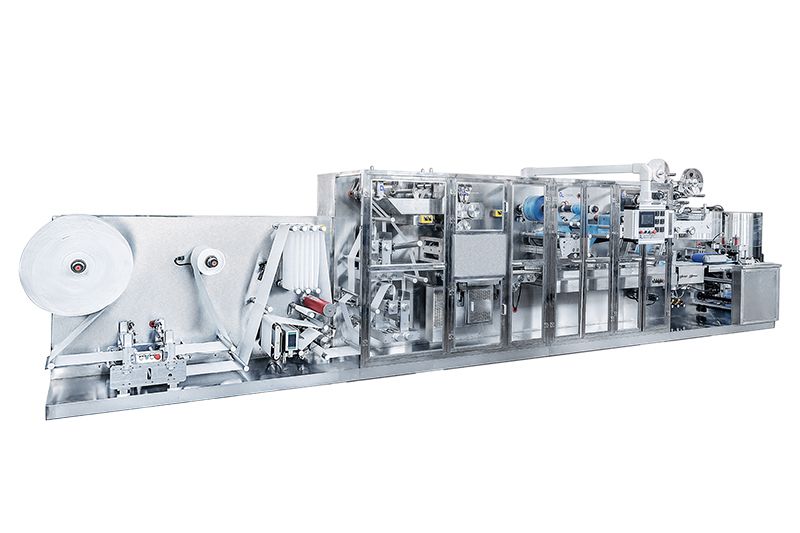

Automatic Unwinding → Automatic Splicing → In-Line Slitting (if needed) → Synchronous Conveying → Longitudinal Folding → Wetting (Soaking) → Cut-Off and Cross Folding → Stacking and Counting → Automatic Packaging → Date Coding → Automatic Hole Punching → Automatic Labeling → Longitudinal Heat Sealing → Automatic Gusseting → Air Take-Out → Transverse Heat Sealing and Cut-Off → Finished Product

| Production speed | 800-1000 wipes/min | Stack count | 5-30 sheet/stack |

| Design speed | 1200 wipes/min | Stack height | Max. 50mm |

| Wipe material | Spunlace nonwoven fabric, wet-strength paper, thermal bond nonwoven fabric | Packaging material | PET/PE BOPP PET/AL/PE (heat sealing materials) |

| Material weight | 35-60g/m² | Number of wrapping film rolls | Wrapping film roll on 2 shafts (automatic splicing, one in operation, one standby) |

| Number of parent rolls | Parent roll on 2 shafts (one in operation, one standby) | Wrapping film roll size | Width: ≤300mm Diameter: ≤350mm |

| Parent roll size | Width: 140-200mm*2 (2 rolls on one shaft) Diameter: < 1200mm (in-line slitting is avaliable for large parent rolls, width 280-400mm*1, diameter < 1200mm) | Package size | Length: 120-330mm Width: 50-100mm Height: 10-50mm |

| Voltage | AC380V 50HZ three-phase five-wire | Label size | Length: 50-150mm Width: 30-80mm Roll diameter: < 350mm |

| Total power | 25kW | Label type | Clear label & non-clear label (dual-shaft labeling, simultaneous running or automatic switching) |

| Open wipe length | 140-200mm | Hole punching size | Length: 20-70mm Width: 15-50mm (hole punching and labeling at the same time) |

| Open wipe width | 140-200mm | Liquid adding tank | 600L×1 304 stainless steel tank with agitator (liquid level detector with alarm function) |

| Folded wipe length | 70-100mm | Air pressure | 0.6-0.8MPa |

| Folded wipe width | 50-80mm | Machine dimensions (L×W×H) | 8500×1520×2350mm |

| Fold type | Z-fold | Liquid tank size | 900×900×1900mm |

| Fold format | Cross folded | Cutting length | 120-230mm (double blade cutting) |

| Wetting range | 2.5-5 times, soaking | Machine weight | Approx. 6t |

Get Tailored Turnkey Solutions for Wet Wipes Packaging