- Production Speed up to 70 lids per minute

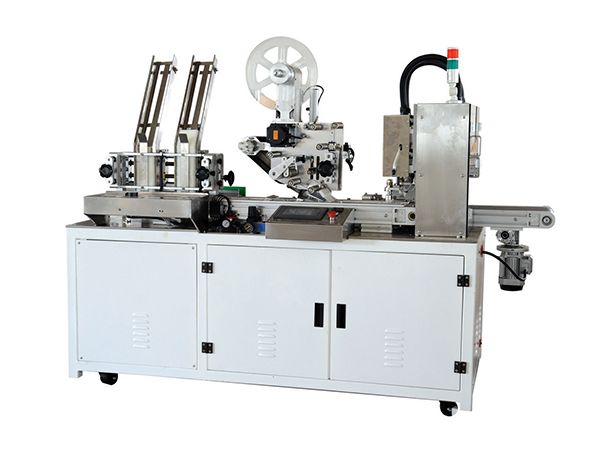

The robotic lid applicator is a high-efficiency, easy-to-operate machine to apply lids on top of packed wet wipes. It is designed to handle a wide range of lid sizes and specifications. With advanced technology and reliable design, it ensures fast, precise lid placement on wet wipes packages with excellent accuracy and consistency.

This lid applicator is engineered for stability and reliability, making it suitable for various industries and production needs. It also prioritizes environmental sustainability, safety, and energy efficiency throughout its design, ensuring that users can operate it with peace of mind. Easy maintenance and user-friendly features save you time, effort, and resources, making it the perfect choice for businesses looking to improve wet wipes production efficiency and maintain high-quality standards.

Lid Placing → Automatic Labeling → Automatic Glue Spraying → Visual Recognition → Lid Application → Finished Product

| Production speed | Max. 70 lids/min |

| Label roll diameter | ≤350mm |

| Label size | Length: 50-100mm Width: 40-100mm |

| Product size | Length: 150-280mm Width: 85-110mm Height: 20-100mm |

| Lid size | Length: 50-180mm Width: 50-120mm Height: 2-10mm Different sizes can be switched within 2 minutes |

| Lid placement accuracy | Longitudinal: ±1mm Transversal: ±1.5mm |

| Label placement accuracy | Longitudinal: ±1mm Transversal: ±1mm |

| Label type | Clear label, printed lable (aluminium foil label is available upon request) |

| Number of label roll | 1 roll |

| Lid storage | 2 storage tanks |

| Display screen | Real-time monitoring of operation, one-key switching of product type |

| Power supply | DC24V, 220V 50Hz 8kW |

| Machine dimensions (L×W×H) | 3300×1200×2000mm |

| Machine weight | 2000kg |

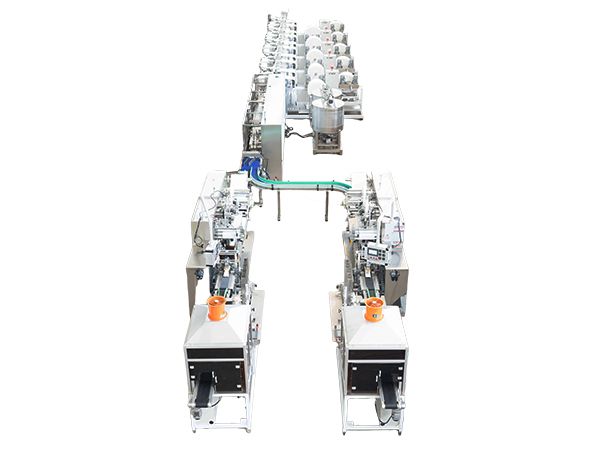

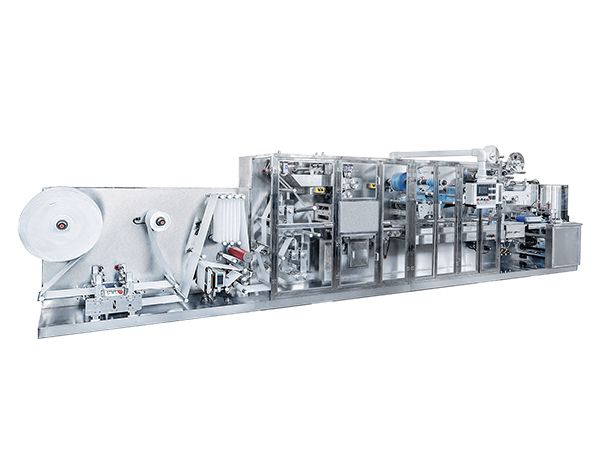

Get Tailored Turnkey Solutions for Wet Wipes Packaging