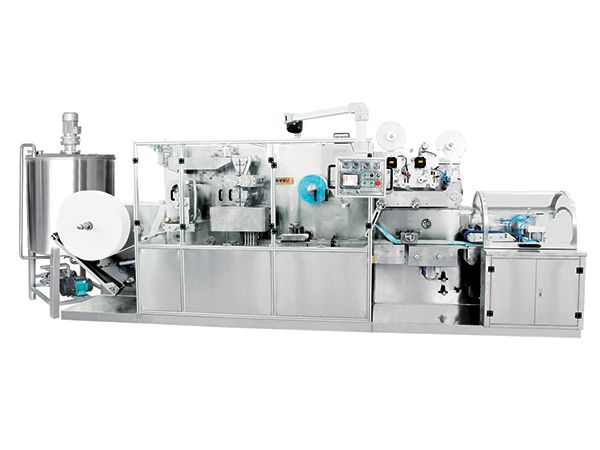

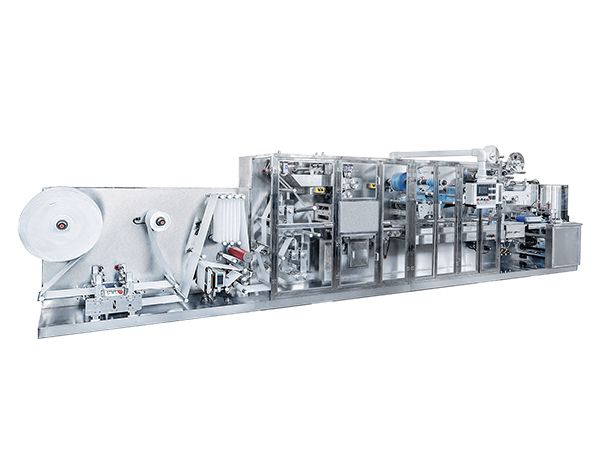

Wet Wipes Machine (5-30 pcs/pack)

Automatic converting machine for pocket wet wipes

Dachang offers wet wipe machines designed for manufacturers producing 5-30 pieces wet wipes per pack. Whether you’re creating daily use wipes, baby wipes, feminine hygiene wipes, sanitary wipes, kitchen wipes, alcohol wipes, or pet wipes, our machines meet diverse production needs with exceptional efficiency and precision.

Want to set your brand apart with top-tier wet wipes production efficiency and consistent product quality? Our fully automatic wet wipe machines are your answer. We provide two options for 5-30 piece wet wipe machine tailored to meet varying production demands, ensuring you stay ahead of the competition.

As a professional wet wipe machine manufacturer, Dachang has 26 years of experience in successfully providing various fully automatic wet wipe folding and packing machines for wet towel manufacturers. In addition to single sheet wet wipe machines, we also provide multi-piece wet tissue machines, including the DC 2020B, DC2020D machines for producing 5-30 pieces/pack wet tissues. To learn more about the technical details, please browse the related pages.

E-Mail

E-Mail Phone

Phone Contact Us

Contact Us